Subcategories

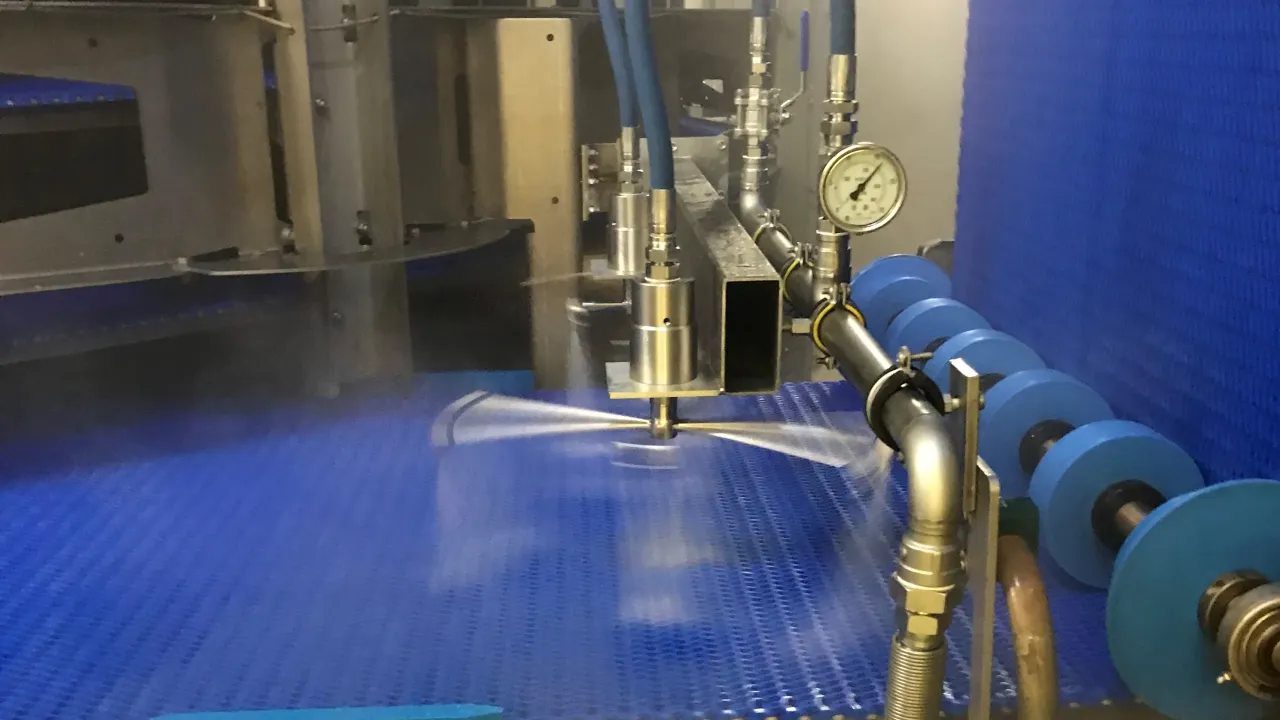

See our Automated Cleaning System in Action

Here you can see our automated cleaning system for belts in action. Engineered for demanding food production environments, this solution provides reliable, repeatable cleaning without the need for manual intervention. By integrating directly into your production line, it minimizes downtime, reduces water and chemical consumption, and extends the lifespan of your conveyor belts. The system ensures compliance with strict hygiene regulations, while lowering operational costs and supporting a more sustainable cleaning process.

How our Automated Cleaning Systems work

Automated cleaning systems from Dosanova are engineered to deliver consistent, high-impact hygiene with minimal manual intervention. By integrating advanced controls, centralized chemical dosing, and powerful cleaning accessories, these systems streamline the cleaning process for conveyors, tanks, and production equipment. Each key component works together to ensure thorough, repeatable cleaning cycles, optimized resource use, and full compliance with the highest food industry standards.

Step By Step guide

1. Air Compressor

The process starts with an air compressor that supplies compressed air to the distribution control center and, if needed, to pneumatic valves or cleaning accessories. Compressed air is essential for actuating valves, powering certain cleaning devices, and enabling blow-out or drying functions within the automated system.

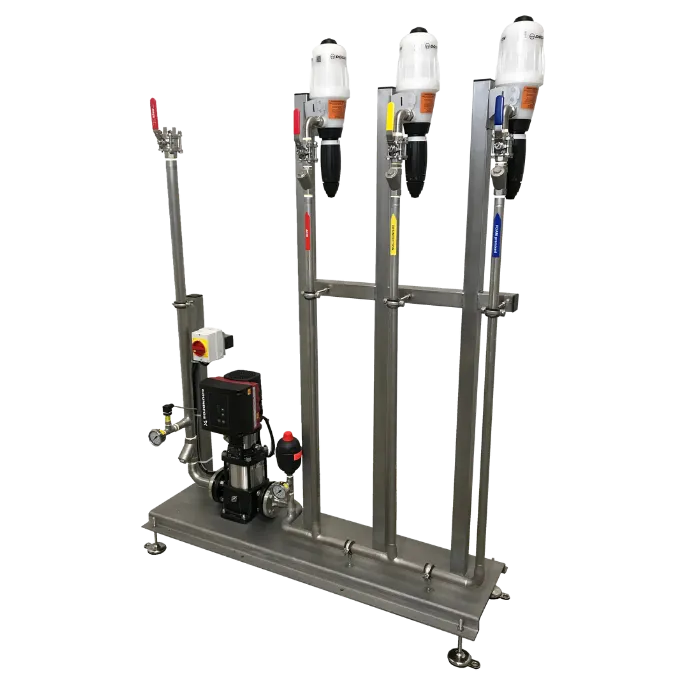

2. Distribution Control Center

This is the “brain” of the automated cleaning system. The distribution control center manages and automates the flow of water, chemicals, and disinfectants to each cleaning zone or device. Programmable valves and automation enable fully customizable, repeatable cleaning cycles for conveyors, tanks, and other equipment.

3. Water Boosters

Centrifugal or triplex water booster pumps ensure a stable, adjustable water pressure throughout the cleaning network. These boosters deliver the required flow and pressure to all cleaning points, enabling effective rinsing, foaming, and disinfection by all connected cleaning devices.

4. Central Chemical Unit (CCU)

The CCU safely stores and precisely doses concentrated cleaning and disinfection chemicals, mixing them with water to create a pre-diluted solution. This solution is supplied at a constant pressure to the distribution control center, ensuring uniform chemical concentration and eliminating the need for chemical handling in production areas.

5. Chemical Stock Storage

Bulk chemical storage tanks are located in a secure technical room, away from production areas. This setup reduces handling risks, improves workplace safety, and enables bulk purchasing of cleaning agents.

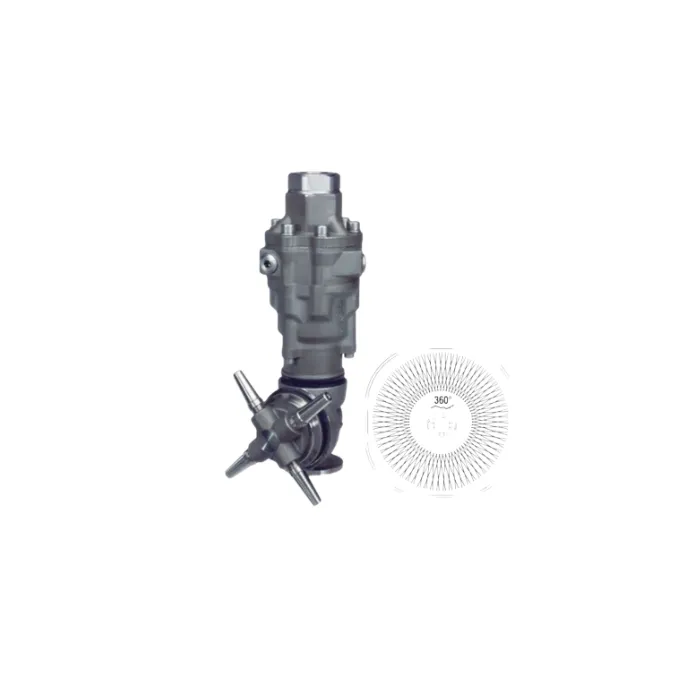

6. Cleaning Accessories (Rotating Nozzles, etc.)

Automated cleaning devices—such as 360° rotating nozzles for tanks, conveyor belt cleaners, and robotic arms—are strategically installed to deliver high-impact, repeatable cleaning. These accessories ensure thorough cleaning of all surfaces, including hard-to-reach “dark spots,” with minimal manual intervention.