Rhinojet - Foam Clean Pro 15

The RhinoJet Foam Clean Pro 15 by Dosanova is a high-performance, air-free foam cleaning system designed for food production, processing plants, and other hygiene-critical industries. Delivering up to 15 L/min at an adjustable pressure from 5 to 200 Bar, it ensures powerful rinsing, disinfection, and consistent foam quality-without the need for compressed air. Dual chemical dosing and ultra-hygienic stainless steel construction guarantee maximum cleaning efficiency, operator safety, and compliance with strict industry standards.

Please note: The product image shown is for illustrative purposes only. Accessories such as the spray gun, hose reel, and other optional items are not included unless explicitly stated in the product description. The final delivered product may differ depending on your selected configuration.

Product Info

Product Height: 540mm

Product Depth: 455mm

The RhinoJet systems comply with the highest safety measures.

Every RhinoJet System is standard equipped with:

-

Dry running protection.

-

Temperature protection.

-

Leak protection.

-

Energy protection. Automatic shut-off after 1 hour of non-use.

-

Thermal protection.

Ways RhinoJet Foam Clean Pro 15 Saves You Money

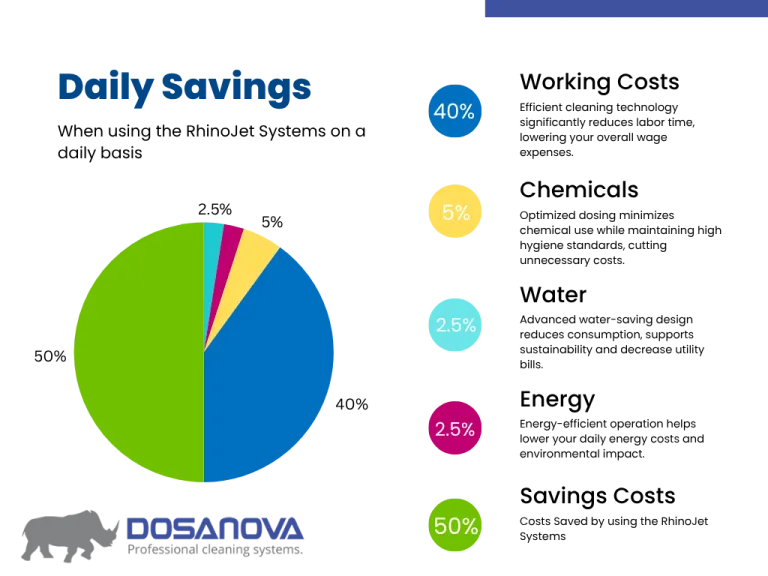

Visualizing Your Savings with RhinoJet Foam Clean Pro

See how your daily cleaning costs break down and where you can save the most. The chart below clearly illustrates the major cost drivers in traditional cleaning processes, highlighting the significant impact of labor, chemicals, water, and energy. By switching to the RhinoJet - Foam Clean Pro 15, you can dramatically reduce these expenses and achieve more efficient, cost-effective daily cleaning.

Frequently Asked Questions

Have questions about cleaning costs, equipment, or how to get the most out of your RhinoJet H15? Our FAQ section covers the most common topics to help you make informed decisions and achieve the best results with your industrial cleaning process. If you don’t find your answer here, feel free to contact our team for personalized support.

Q: What is the RhinoJet - Foam Clean Pro 15, and where is it used?

A: The RhinoJet - Foam Clean Pro 15 is a high-pressure, air-free foam cleaning station from Dosanova, designed for professional foam cleaning, rinsing, and disinfection in food production, processing plants, and other hygiene-critical industrial environments. It delivers up to 15 L/min at pressures up to 150 bar, ensuring powerful and efficient cleaning performance.

Q: How many users can operate the RhinoJet - Foam Clean Pro 15 at once?

A: The RhinoJet - Foam Clean Pro 15 is designed for use by one operator at a time, providing consistent high-pressure cleaning at a fixed location.

Q: What cleaning functions does the RhinoJet - Foam Clean Pro 15 provide?

A: The Foam Clean Pro 15 offers three main cleaning functions: foam cleaning, rinsing, and disinfection. Operators can easily switch between these modes for flexible, thorough cleaning in demanding environments.

Q: Does the RhinoJet - Foam Clean Pro 15 require compressed air for foam generation?

A: No, the RhinoJet - Foam Clean Pro 15 uses Dosanova’s air-free foam technology, generating rich, stable foam directly at the lance without the need for a compressed air supply. This simplifies installation and ensures consistent foam quality, even over long hose lengths.

Q: How does chemical dosing work on the RhinoJet - Foam Clean Pro 15?

A: The station features two fully separated chemical injectors, allowing for safe and precise dosing of two different chemicals (such as detergent and disinfectant). Dosing ratios are adjustable from 0.15% to 15%, with color-coded suction kits to prevent mix-ups.

Q: What safety and hygiene features does the RhinoJet - Foam Clean Pro 15include?

A: The Foam Clean Pro 15 features a stainless steel chassis and sloped cover for optimal hygiene, dry running protection, pressure regulator with bypass, TST automatic stop system, SBS complete shut-off, DSS drop stop system, SWL security water level system, and color-coded chemical suction kits. All parts are easily accessible for maintenance, and the unit is CE approved.

Q: What are the installation requirements, and can Dosanova handle the setup?

A: The RhinoJet - Foam Clean Pro 15 requires a water supply (2–6 bar, minimum 20 L/min), a 3x400V electrical connection, and standard drainage. Dosanova offers full professional installation and commissioning services to ensure your system is set up correctly and operates at peak efficiency.

Q: Where can I find more technical details or documentation?

A: Technical datasheets, brochures, and installation guides are available for download on the Dosanova website or upon request.

Ready to Upgrade Your Cleaning?

Contact our team for expert advice, more information, or a personalized quote for the RhinoJet H15. We’re here to help you find the best cleaning solution for your facility.